"A recent Wall Street Journal op-ed, “Bringing the Factories Home: Any new industrial policy has to make the U.S. less vulnerable to Chinese suppliers,” by Hudson Institute Senior Fellow Arthur Herman, adds little to the debate over what to do about China.

Plans to “bring the factories home” come with great risks. One that is rarely mentioned is the likelihood that other countries may decide to copy this policy and “take the factories home.” For the 2.6 million American manufacturing workers employed by foreign-owned companies that have built U.S. factories, this would be a devastating result.

Perhaps the key takeaway from the piece is embodied in the suggestion that the federal government should tell Apple, one of the most innovative and successful companies in American history, how to produce iPhones.

Mr. Herman further suggests that China has a stranglehold on American’s access to important health-care goods like ventilators, and therefore the government should reduce American “dependence” on China-sourced pharmaceuticals and health-care products.

Last year, China accounted for 17 percent of all U.S. ventilator imports. That’s hardly a stranglehold.

Overall, more than half of medical goods and pharmaceuticals used in the USA are made in the USA. China accounts for about 2 percent of the combined U.S. market for medical goods and pharmaceuticals.

According to Mr. Herman, 97 percent of antibiotics used in America are sourced from China. It’s not clear where that statistic comes from. According to data from the U.S. International Trade Commission, about 2.4 percent of U.S. antibiotic imports came from China in 2019.

Perhaps he is referring to “Active Pharmaceutical Ingredients” (APIs) imported from China.

According to March 2019 testimony from the Food and Drug Administration (FDA), “we cannot determine with any precision the volume of API that China is actually producing, or the volume of APIs manufactured in China that is entering the U.S. market.” In June 2020, an FDA spokesman reiterated this: “Data available to FDA do not enable us to calculate the volume of API being used for U.S.-marketed drugs from China or India, and what percentage of U.S. drug consumption this represents.”

This lack of data is certainly problematic. It was addressed by Congress in a CARES Act provision authorizing research to get to the bottom of this. In the meantime, there is no reason to believe that 97 percent of U.S. antibiotics are sourced from China.

Mr. Herman adds: “Asia produces 90 percent of the world’s circuit boards—more than half of them in China.”

This statement is reminiscent of the time Scott Williams (2 points) and Michael Jordan (55 points) combined for 57 points in game 4 of the 1993 NBA finals. Why commingle production by China with that of Japan, Korea, Taiwan, and other U.S. allies? More fundamentally, if U.S. manufacturers can procure affordable circuit boards for garage door openers and refrigerators from abroad, how exactly does that threaten American security?

He repeats this tactic with respect to STEM education: “A 2019 Congressional Research Service report found that India and China together made up nearly 70 percent of foreign students enrolled in STEM courses in the U.S.” It makes even less sense to lump together India and China than it does to combine the scores of Michael Jordan and Scott Williams, unless the goal is to concoct a big, scary number.

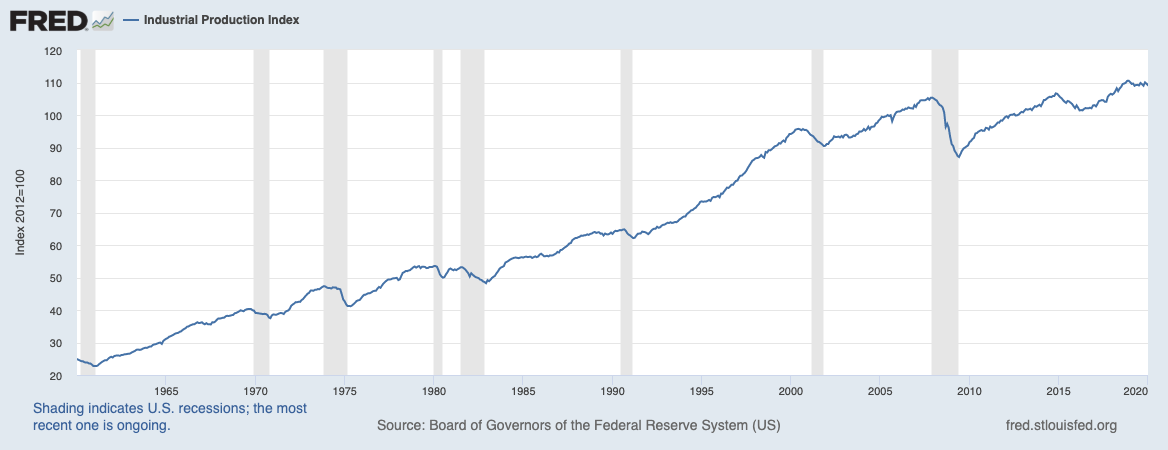

Mr. Herman is concerned that manufacturing now makes up 11 percent of U.S. gross domestic product (GDP), compared to 25 percent in the 1960s, and that more than five million American manufacturing jobs have been lost since 2000.

It seems that critics of American manufacturing capacity will look at any measure except for how much we manufacture to justify their policy prescriptions.

Manufacturing output has steadily increased over the years. There is no reason Americans should be concerned that other areas of the economy have grown even more, reducing manufacturing’s share of total GDP.

Nor should Americans be concerned that technological advancements made U.S. workers more productive than ever, reducing the number of manufacturing jobs. The economy added new jobs elsewhere, and overall employment grew.

If there’s a problem with that, the easiest fix would be to fire all the country’s doctors, accountants, teachers, and plumbers and ban all imports of affordable clothing. Manufacturing’s share of GDP would increase, and more Americans could return to factories to run sewing machines 40 hours a week.

As is always the case with industrial policy advocates, the proposed solution to the misdiagnosed problem involves the federal government picking winners and losers -- specifically, “Washington should identify commercial-sector technologies that may be crucial to national security. Artificial intelligence, robotics, quantum technologies and nanotechnology all need a strong domestic manufacturing base.”

Perhaps there are those who sincerely believe in the existence of some wizard or super-computer or fortune-teller or bureaucrat who knows the future, and who can use that knowledge to decide how much money to take from farmer A to throw at robotics company B instead of robotics company C or nanotechnology company D. But history suggests that limiting federal involvement to specific, targeted national security needs is an approach that’s much more likely to work.

Telling pharmaceutical companies how to make drugs and Apple how to make iPhones would make us weaker and worse-off.

Data Notes:

Ventilator imports based on HTS number 9019.20.0000, “ozone therapy, oxygen therapy, aerosol therapy, artificial respiration or other therapeutic respiration apparatus; parts and accessories.”

Medical goods calculations based on NAICS number 3254, "Pharmaceutical and Medicine Manufacturing," and NAICS number 3391, "Medical Equipment and Supplies Manufacturing."

Antibiotic imports based on HTS number 3004.10, “medicaments, in measured doses, etc., containing penicillins or derivatives thereof, or streptomycins or their derivatives,” and HTS number 3004.20, “medicaments, in measured doses, etc., containing antibiotics, nesoi.”"

Thursday, July 23, 2020

We don't need to worry about China dominating the supply chain for antibiotics or anything else

See No, The Government Should Not Tell Apple How To Make iPhones by Bryan Riley. Bryan Riley is Director of NTU’s Free Trade Initiative.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.